Galvanized Welded Roof Safety Mesh for Fall Protection

RSM-1: Roof safety mesh with anti-corrosion and UV stabilized is used for housing roof construction.

Roof safety mesh is formed by welding of zinc coating wires using electric resistance techniques under pressure. Welded roof safety mesh is a primary means for fall protection when persons working at heights in domestic, commercial and industrial building applications and housing roof construction that use metal or timber purlins, or a tested supporting member.

Roof safety mesh coverage

Roof safety mesh shall be installed over the entire roof area, including penetrations, and remain in place for fall protection.

Standard roofing safety mesh complies with

Our roof safety mesh complies with Australian/New Zealand - standard AS/NZS 4389:2015 roof safety mesh.

Welded roof safety mesh features

- The wires are clean, smooth and free from defects detrimental to its subsequent processing and end use.

- Wire with zinc coating and UV stabilized.

- Mesh construction shall be formed by welding of wires using electric resistance techniques under pressure.

- Apart from the cut ends, roof safety mesh is clean and free of defects, sharp edges, burrs and similar imperfections that may cause injury to the handler or installer.

Roof safety mesh specifications, staples and fasteners needed for mesh installation.

| Minimum nominal diameter of wire mesh | Minimum mass of zinc coating | Minimum tensile strengths of transverse wire | Minimum tensile strengths of longitudinal wire |

|---|---|---|---|

| 2.00 mm | 35 g/m2 | 450 MPa | 500 MPa |

| Spacing of longitudinal wires | Spacing of transverse wires | Length of the mesh roll | Width of the mesh roll | Nominal weight of the mesh roll |

|---|---|---|---|---|

| 150 ± 5 mm | 300 ± 5 mm | 50 m | 1.8 m | 24 kg |

| Minimum mass of zinc coating | Minimum nominal diameter of staple wire | Minimum length of staple | Maximum spacing of staples | |

|---|---|---|---|---|

| Stapling onto side of of staples timber rafter | Staples on top of timber rafter | |||

| 35 g/m2 | 3.15 mm | 30 mm | 40 mm | 155 mm |

| Crown width of fastener | Opening width of fastener | Coating type | Fastener size |

|---|---|---|---|

| 22 mm | 16 mm | Galvanized | 1.90 mm diameter or equivalent strip |

Installation requirements

The installation of roof safety mesh shall comply with the following steps:

- Position of roof safety mesh.

- Fixing of roof safety mesh.

- Joining rolls or sections.

RSM-2: Roof safety mesh longitudinal wire joining.

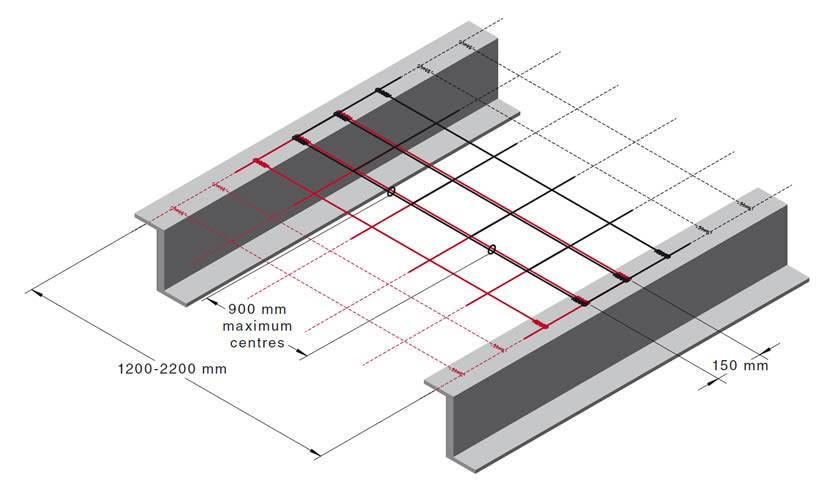

RSM-3: Side lapping of roofing safety mesh. For purlin spacing 1200-2200 mm, fasteners to be fitted at maximum of 900 mm centres and minimum single lap. For purlin spacing greater than 2200 mm, fasteners to be fitted at maximum 600 mm centres and minimum double lap.

In order to better understand safety mesh, please see the terms of roof safety mesh.