Welded Wire Mine Support Mesh - Steel Wire or Reinforced Bars

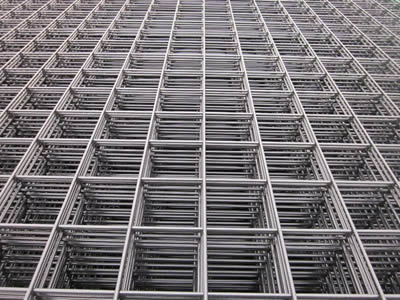

WWSM-01: Welded wire supporting mesh can supply efficient and durable construction.

In the history, there was so many types of coal mine supporting ways to ensure the coal mine tunnel security, including various anchor bars, sticks, bamboo chips. They were waste of materials and had a small function for the roadway security. Nowadays, there are so many kinds of coal mine supporting meshes to secure the tunnel safety.

The coal mine supporting meshes are made of plastic materials, steel wires or steel plastic composite materials, which have high tensile strength and breaking strength to ensure the stability and safety. Compared with single anchor bars, which supplies several point protection, the coal mine supporting mesh can supply a whole protection for tunnel. We can supply all kinds of coal mine supporting meshes for you. The main products are welded wire mine support mesh.

Welded wire mine support mesh is a common seen and widely used type in coal mine supporting mesh. It is efficient and energy saving type supporting mesh. Adopts thicker steel wires or reinforced bars as material, the welded wire meshes are spot welded into tough structure with square meshes. Compared with chain link mesh and other woven wire meshes, the solid weld point supplies double protection for the roadway. Additional, the solid structure can improve the stability and safety coefficient. It can make the construction faster and easier. The welded wire mesh is available for shotcrete applications to make the construction faster, easier and safer.

Specifications of welded wire mine support mesh

- Material: low carbon steel wire or galvanized steel wire.

- Wire diameter: 2 mm to 10 mm. Special sizes can be customized.

- Mesh size: commonly is 30 mm × 30 mm, 50 mm × 50 mm, 100 mm × 100 mm, 150 mm × 150 mm, 200 mm × 200 mm.

- Panel size: 1 m × 2 m is the most widely used. Special sizes can be customized.

WWSM-02: Thinner diameter welded wire mesh panels.

WWSM-03: Thicker diameter reinforced bar welded wire mesh.

Features of welded wire mine supporting mesh

- High precision and little tolerance.

- Made of high tensile strength steel wires.

- Various configurations and sizes.

- Solid structure for durable life.

- Easy to install and replace.

- Suitable for shotcrete applications.

- Used for loose strata to avoid rock falling.

WWSM-04: High quality materials can ensure the good performance of supporting mesh.

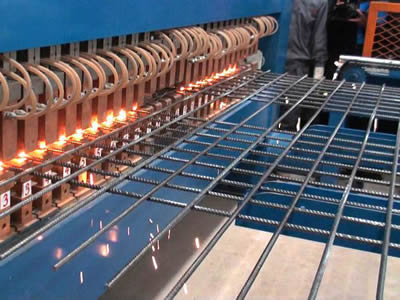

WWSM-05: Automatic welding machine ensures the accuracy of meshes and panel sizes.

WWSM-06: Metal pallet package for easy loading and transporting.

WWSM-07: Plastic film package can protect welded wire mesh from corrosion during transporting.

Related products

Except for the welded wire supporting mesh, we can also supply the following types coal mine supporting mesh for your choice.

- Chain link mesh. Flexible and soft structure for roadway roof and sidewall protection.

- Crimped wire mesh. Crimped and woven structure for coal mine tunnel security.

- Woven wire mesh. Simple but high tensile strength woven structure for security.

- Bilateral stretched plastic mesh. Bilateral stretch supplies even meshes and high strength to mine roadway roof and sidewall.

- Steel plastic composite mesh. High tensile strength, fire retardant and great breaking strength.

WWSM-08: Chain link mine supporting mesh.

WWSM-09: Woven wire mine supporting mesh.

WWSM-10: Bilateral stretched plastic mine supporting mesh.

WWSM-11: Steel plastic composite mine supporting mesh.

WWSM-12: Crimped wire mine supporting mesh.