Welded Steel Grating for Walkways and Industrial Flooring

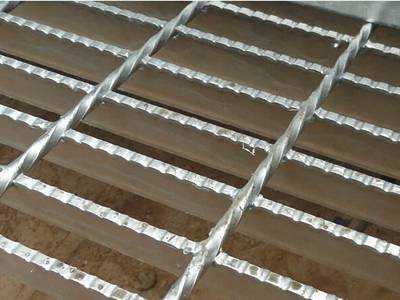

Welded steel grating is manufactured using an automated process combining hydraulic pressure with a powerful electric welding current which electro-forges the bearing bars and the cross bars to form a single rigid panel. Welded Steel Bar Grating is the most popular of all grating types due to its strength, cost-efficient production and ease of installation. Universally used in most general industrial plants as well as commercial buildings, it has wide applications as walkways, platforms, safety barriers, drainage covers and ventilation grates.

WSG-01: Welded steel grating 1

WSG-02: Welded steel grating 2

When selecting a bar grating product, consider Welded Steel Grating first. Usually our most economical products, they provide a comfortable walking surface with nearly 80 percent open area. This, combined with the positive welded cross bar/bearing bar intersection, make these products our most popular. Manufactured from carbon steel, welded gratings are recommended for nearly all industrial flooring applications.

WSG-03: Welded steel grating 3

WSG-04: Welded steel grating 4

WSG-05: Welded steel grating 5

WSG-06: Welded steel grating 6

WSG-07: Welded steel grating 7

WSG-08: Welded steel grating 8

WSG-09: Welded steel grating 9

WSG-10: Welded steel grating 10

WSG-11: Welded steel grating 11

WSG-12: Welded steel grating 12

WSG-13: Welded steel grating 13

WSG-14: Welded steel grating 14

- Grating shall be Amico Standard Welded Type "W" 19W4 resistance welded grating as manufactured by Alabama Metal Industries Corp. or approved equal.

- Bearing bars: Rectangular steel bars of an appropriate depth and thickness for the required load, on 1 3/16" centers. Other available centers are; (15/16"; 13/16"; 11/16"; 5/8"; and 1/2") which may be selected at the discretion of the Architect/Engineer.

- Cross Bars: Twisted wire rod, at 4" on center, resistance welded to the bearing bars and at right angles to them. Other available center is 2" as may be selected by the Architect/Engineer.

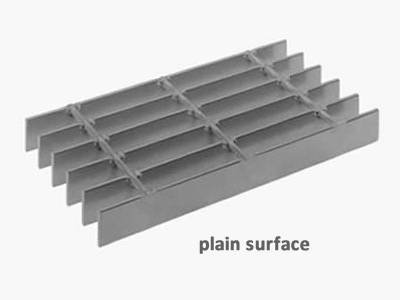

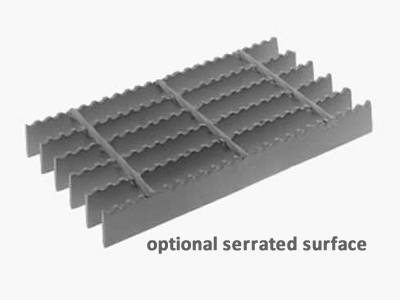

- Surface: The bearing bars shall have a smooth top surface unless the Architect / Engineer determines the need for a serrated surface.

- Loading: At a uniform load of 100 pounds per square foot, deflection shall not exceed ¼ inch over the required span.

- Finish: Manufacturers standard shop coat of black paint or Galvanized as required by Architect/Engineer.

Welded steel grating application:

- Barriers.

- Walkways.

- Ladder rungs.

- Industrial flooring.

- Waste water treatment.

- Bellagio project.

WSG-15: Welded steel gratings in workshop

WSG-16: Welded steel grating in 6 m length

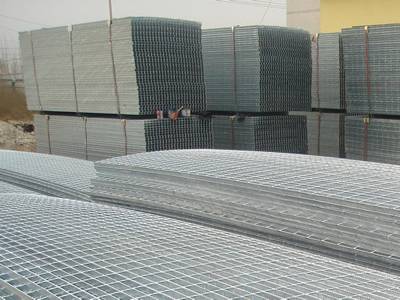

WSG-17: Welded bar grating pallet package

WSG-18: Welded bar grating for delivery