Coal mine roadways support has experienced a long process from the wood supporting, arching support, steel support to bolt support. Nowadays, welded wore mesh rock bolting which is regarded as a safe and efficient supporting way has become the first choice of coal mine roadway.

The complete bolting techniques for coal mine roadways

Bolting techniques for coal mine roadways is a huge system, including the surrounding rock geological mechanics test, bolting supporting design, supporting materials, construction machinery and technology, support engineering quality testing, monitoring of mine pressure, special geological conditions supporting technology and so forth.

- Geomechanics testing

Adequate and reliable geomechanical parameters provide the necessary basis for roadway layout and support design. - The dynamic information method for bolting design

In the design of bolt supporting, mutual matching between anchor and each component of anchor cable support plays a very important role in taking the effect of each component and support system. The bolt and nut should match the strength of the rod, the mechanical properties of the anchoring agent should match with the rod body, and the form and mechanical parameters of the composite component and metal mesh should be matched with the rod body. The matching between the anchor cable and the supporting plate, the composite component and the metal mesh (such as welded steel wire mesh, chain link fence, crimped mesh) is similar to the bolt. High prestress and high strength anchor rod body should be equipped with high strength arch plate, high strength nut and high efficiency friction reducing gasket. Composite components should be matched with W type steel strip with high strength, high rigidity and large surface area. In addition, metal mesh should adopt welded wire mesh with high strength and high rigidity. For high prestress and high-strength anchor cable, we should use high-strength arch pallet to achieve the effective diffusion of anchor cable prestress and working resistance. Otherwise, the failure of any supporting member will affect the supporting effect, or even lead to the failure of the whole supporting system. In addition, the anchor should match with the form, parameters and mechanical properties of the anchor cable reciprocally to make anchor bolt and anchor cable play the supporting role together. - The materials of high strength bolts and cables

In order to adapt to the complicated and difficult roadway conditions, a series of high strength bolt supporting materials are developed. Through the optimization of the structure and shape of the rod, we can improve the anchoring effect. At the same time, by developing special steel for anchor rod, we can achieve high strength and ultra-high strength level. In the aspect of prestressed anchor cable support, a large diameter and high tonnage anchor cable is developed. Cable diameter is 22 mm, tensile load of 600 kN. - The construction quality detecting and monitoring techniques

- The combination techniques of bolting and grouting

WWMR-01: Welded wire mesh rock bolting in coal mine roadways can achieve the effective diffusion of anchor cable prestress and working resistance.

WWMR-02: The construction of welded wire mesh rock bolting need adequate geomechanical parameters.

Typical application example analysis of bolt support design

WWMR-03: Welded wire mesh is suitable for using as rock bolting in coal mine roadways.

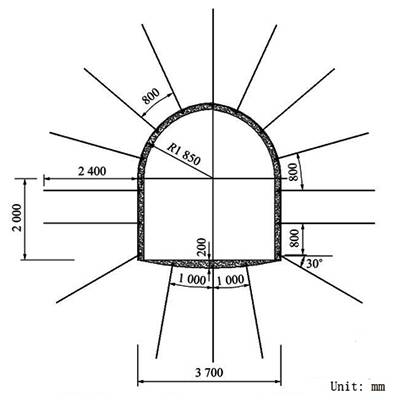

- High stress rock roadway support technology for kilometer-depth well

Through the numerical simulation analysis, it is confirmed that the supporting form of the transportation roadway is: high prestress, long resin anchoring and strong bolt supporting, and spraying concrete. The body of anchor rod adopts 25-millimeter-diameter vertical reinforced concrete anchor rod, whose length is 2.4 m and ultimate tensile stress is 400 kN. Its yield force is 294 kN and elongation is 18%. The pretightening force is designed to be 80 kN with resin lengthening anchor. It adopts W type steel guard plate and 50 mm mesh reinforcement welded steel mesh top and guard, whose diameter is 8 mm. The distance between the top plate and the two anchor bolts is 800 mm with each row of 13 anchor bolts. Each row has 3 floor bolts with spacing of 1000 mm and row spacing of 800 mm.

Spray concrete: After the excavation of the tunnel, immediately spray 30-millimeter-thickness concrete to make a temporary supporting. Then fill the over digging part of the roadway. After completing the construction of the anchor, install the anchor bolt at the place 50 meters behind the working face. Then, carry out twice shotcrete construction and the spraying thickness is 120 mm. - Support technology of soft rock roadway

The numerical simulation is used to compare the different schemes, and the existing experience has been used to determine the full length prestressed anchor combined support. The body of anchor rod adopts 22-millimeter-diameter vertical reinforced concrete anchor rod, whose length is 2.4 m. The whole length of the resin is anchored, the end of which is made of fast curing anchoring agent, and the slow curing anchorage is used at the back. It adopts W type steel guard plate and 50 mm mesh opening reinforcement welded mesh (8 mm wire diameter) top and chain link mesh for surface. The anchor bolts are perpendicular to the roadway surface. Each row has 7 floor bolts with spacing of 850 mm and row spacing of 900 mm. The distance between the top plate and the two anchor bolts is 600 mm with each row of 2 anchor bolts. It pretightening force is 400 N·m.

22 mm anchor cable, steel wire with a length of 4.3 m and a length of 1. Every 1.8 m hit 3 anchor cable spacing of 1.28 M. The pretightening force of cable is 200–250 kN. - The influence of strong active mining activity on roadway support technology

According to the results of theoretical analysis and numerical simulation, it adopts full length and high prestressed anchorage, the short strong anchor cable, and the vertical rock surface of the whole section as the support method of the tile lane. The parameters of anchor cable support are as following: the cable body is 22-millimeter-diameter steel strand of 1 × 19 and its length is 4.3 m. After anchoring, the end of the resin is prestressed and the rest part adopts cement paste full-length anchorage. The anchor rope supporting plate is a piece of high-strength adjustable plate in 300 mm × 300 mm × 16 mm. It also adopts 10 mm steel wire 60 mm mesh opening reinforcement welded steel mesh top and guard. Each row has 5 anchor bolts with spacing of 900 mm and row spacing of 1200 mm. The distance between the top plate and the two anchor bolts is 1200 mm with each row of 3 anchor bolts. The anchor bolts are perpendicular to the roadway surface and the pretightening force of cable is 200–250 kN. - Support technology of large section rectangular tunnel

Based on the theoretical analysis and numerical simulation, we choose the combined support system with high prestress, strong bolt and anchor cable.

Roof supporting: The body of BHRB600 type anchor rod is the 22-millimeter-diameter vertical reinforced concrete anchor rod, whose length is 2.8 m. The tensile force of the rod is not less than 300 kN and the resin is lengthened and anchored. It adopts W type steel guard plate and 50 mm reinforcement welded wire mesh top and guard with strips whose thickness is 4 mm and width is 280 mm. Each row has 9 floor bolts with spacing of 850 mm and row spacing of 1000 mm. In addition, the cable body is 22-millimeter-diameter steel strand of 1 × 19 and its length is 9.3 m and the anchor rope supporting plate is a piece of high-strength adjustable plate in 300 mm × 300 mm × 16 mm. The distance between the top plate and the two anchor bolts is 600 mm with each row of 4 anchor bolts. Its roof bolt pretightening force is 400 N × m and the pretightening force of cable is 200–250 kN. Roadway support is divided into gob side and inner side.

Gob side: It adopts the 22-millimeter-diameter vertical reinforced concrete anchor rod, whose length is 2.4 m and resin lengthening anchor. Steel joist adopts 14-millimeter-diameter welded steel with the width of 80 mm. Each row has 5 anchor bolts with spacing of 950 mm and row spacing of 1000 mm. The body of anchor rod adopts 17.8-millimeter-diameter vertical reinforced concrete anchor rod, whose length is 5.3 m. Each row has two anchor wires and the distance between them is 2 m.

Inner side: Open-off-cut drilling adopts secondary tunneling to form the roadway. The first digging position is close to the tail lane and the drilling width is 4.5 m. Due to secondary tunneling, fiberglass reinforced plastic bolts should be applied on the inner side of the primary and secondary tunneling. It adopts 20-millimeter-diameter fiberglass reinforced plastic anchor rod whose length is 2.4 m, resin lengthening anchor and plastic mesh for surface protection. Each row has 6 anchor bolts with spacing of 750 mm and row spacing of 1000 mm. - Support technology of gob-side entry driving with small pillar

According to the site conditions and numerical simulation, we can make sure the initial design of support.

Roof supporting: W type steel strip combined bolt support is cooperate with anchor cable reinforcement. It adopts BHRB600 type anchor rod, the 22-millimeter-diameter vertical reinforced concrete anchor rod, whose length is 2.8 m. It also chooses 4.8-meter-long W type steel guard plate whose thickness is 4 mm and width is 280 mm, and 100 mm mesh reinforcement welded steel wire mesh top and guard with 10 mm diameter. Anchor bolts have spacing of 750 mm and row spacing of 1000 mm. 22-millimeter-diameter anchor wire which is 7 meters long. Resin lengthening anchor is with three-flower arrangement and row spacing of 1000 mm.

Two side supporting: Its supporting form is the same as the roof supporting. The difference between them is that the row spacing of small coal pillar side bolt is 800 mm, while the row spacing of the bolt on the other side is 900 mm. - Support technology of deep gob side entry retaining

Return airway adopts resin lengthened anchor bolt, anchor cable combined support and bolt support along gob side entry. The body of BHRB500 type anchor rod is the 22-millimeter-diameter vertical reinforced concrete anchor rod, whose length is 2.4 m. It also chooses W type steel guard plate and 50 mm reinforcement welded mesh roof supporting with 6 mm diameter. Each row has 6 anchor bolts with spacing of 900 mm and row spacing of 1000 mm. Its anchor bolt pretightening force is 500 N × m. In addition, the cable body is 22-millimeter-diameter steel strand of 1 × 19 and its length is 6.3 m. Install 2 anchor cables every 2 meters and its pretightening force is 300 kN. The bolt size of roadway is the same as roof bolt. The row spacing between the anchor bolts is 1000 mm with the upper side of 4 anchor and under side of the 2 anchor. - Supporting technology of gob side entry

The original supporting way is bolt supporting which must be reinforced. With the combination of high strength bolt and anchor cable, parameters of anchor cable support are as following: The roof is a 22-millimeter-diameter high-strength steel bolt, whose length is 2.4 meters, with full-length anchorage. It adopts anchor bolts with spacing of 1000 mm and row spacing of 900 mm. It also chooses W type steel roof and 7-meter-long anchor wires with spacing of 1.8 m. There are 16-millimeter-diameter round bar anchors whose length are 2 mm and end anchorage with bolt spacing of 1.4 m and row spacing of 700 mm. - Reinforcement technology of grouting and anchoring in soft fractured surrounding rock chamber

Sectional grouting and full grouting are applied. When adopting sectional grouting, the length of each section is 10 m. The grouting pressure near shaft is controlled within 3 MPa and the grouting pressure of the remaining grouting hole is controlled around 6 MPa.

The diameter of strength bolt is 25 mm and its length is 2.4 m. Its yield strength is 600 MPa and rupture strength is 800 MPa. The pretightening force of anchor bolt is 500 N × m. It also adopts 50 mm mesh reinforcement welded mesh top and guard, whose diameter is 6 mm. The row spacing of anchor bolts is 1 m.

Recommended specifications of suitable welded wire mesh for coal mine supporting:

- Material: low carbon steel wire or galvanized steel wire.

- Wire diameter: 2 mm to 10 mm.

- Mesh size: 30 mm × 30 mm, 50 mm × 50 mm, 100 mm × 100 mm, 150 mm × 150 mm, 200 mm × 200 mm.

- Panel size: 1 m × 2 m.